Introduction

It is important that racks be regularly inspected and correctly maintained to retain the original system’s design capacity and factors of safety. Users need short-term and long-term strategies to address damage that occurs in their facility.

It is important to keep in mind that rack repair could void manufacturer’s warranties and guarantees because original equipment manufacturers lack control over the repair process. Such a situation involving subsequent modifications could shift responsibility for product liability from the original rack manufacturer to the end user.

When rack is damaged or improperly repaired, the load-carrying capacity of the structure may be reduced. Although a single instance of damage to the rack may not result in failure, severe or accumulated damage will reduce the capacity of the system and may ultimately lead to its collapse. The cost of rack collapses may far exceed the value of the entire rack structure and may lead to: injury or loss of life, loss of product, loss of business and business interruption, large cleanup and replacement expenses and/or costly litigation.

Rack repair is typically the responsibility of: maintenance staff, the safety committee or a professional third-party. The last page of this guide includes a check-list to assist in future rack inspections.

How to Determine if the Rack is Damaged Enough to Repair/Replace

Is That Upright Damaged?

Not all rack damage is created equal. There isn’t much in the way of guidance provided by the United States to answer the question: How damage to an upright is too much? So, some of our guidance comes from the United Kingdom and some comes from on the job experience.

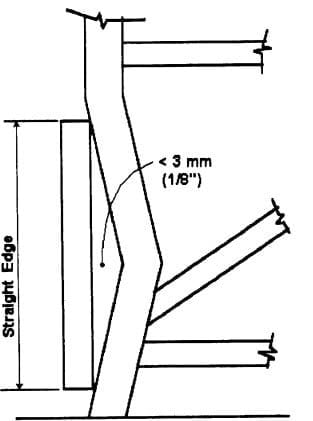

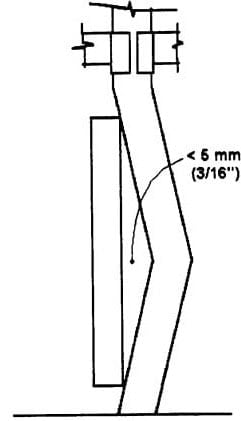

A. Struck from the Side or Head-On

In the case above, it is recommended to limit cross-aisle deviation to 3/16” while down aisle deviation should be limited to about 1/4”. If the damage falls outside of this, it should be repaired or replaced.

B. Column is Twisted, Punctured or Missing Bracing

A post that is twisted, punctured or missing bracing always needs to be repaired or replaced regardless of how ‘bad’ the damage looks. Bracing is required to both resist forces arising from lateral loads and adequately brace the vertical members. Its absence or damage will significantly reduce the capacity of the system.

Additional questions to consider:

- Does the post show signs of rust?

- Do any uprights require the protective devices (post protectors, etc.) to be replaced?

- Is the hardware no longer in a ‘like-new’ condition?

If you answered ‘yes’ to any of these, you should consider repairing or replacing the column as these are evidence either of past damage or improper handling.

Is That Beam Damaged?

RMI requires a safety lock be capable of withstanding 1,000 pounds of upward force to prevent it from popping out if hit from the bottom. Generally, damage in this sense if caused by an operator lifting the load too high during retrieval. This results in the top of the product hitting the bottom of the beam. While it typically results in extensive damage to the product, there isn’t much noticeable damage to the beam.

So, a couple of things to consider when checking for damage to beams:

- Is there enough clearance between the top of the pallet and the bottom of the beam (6” is recommended)?

- Are all safety locks still installed on the beams? (don’t forget to check the beams that don’t face the aisle)

- Do they exhibit an upward bow or show contact marks?

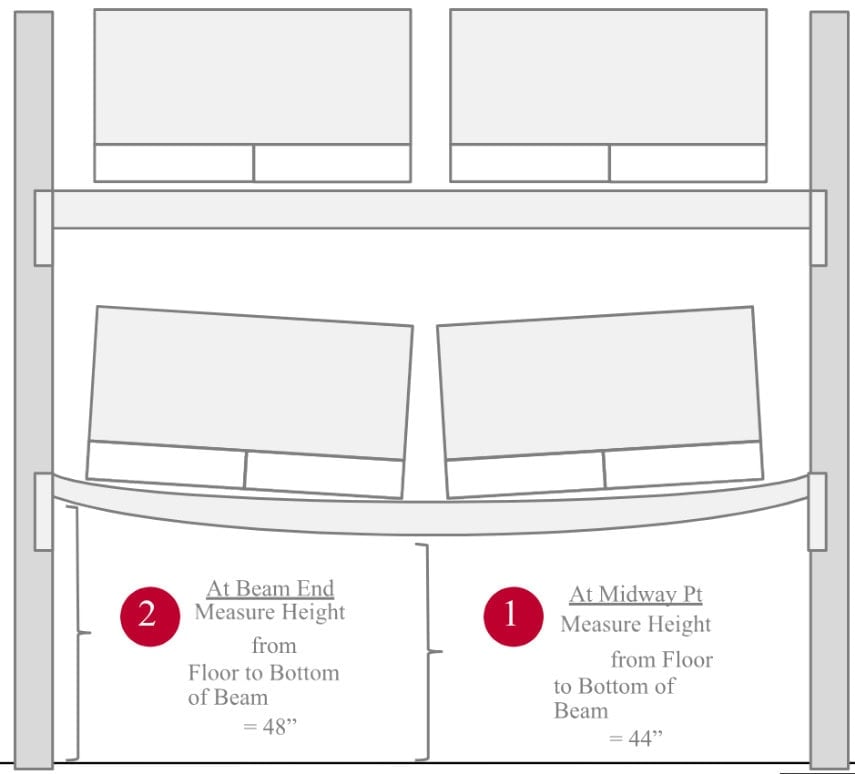

- Is the beam showing deflection?

While beam deflection is normal, in some cases it can be a sign of potential future failure. You need to pay particular attention to deflection when utilizing used beams or if your racks have been overloaded in the past. These scenarios could result in as much as a 25 percent degradation in the deflection capacity!

To calculate the amount of allowable deflection, divide the beam length (in inches) by 180. According to The Rack Manufacturers Institute (RMI), most beams are designed to withstand deflection up to 1/180th or 0.055% of the beam length (in inches).

= 48 – 44

= 4”

Allowable Deflection

= Beam Length / 180

= 96” / 180

= 0.5”

Beam deflection of 4” is outside allowable range of 0.5”

Just because a beam exceeds this deflection, does not mean that the beam is on the verge of collapse. But, all of the personnel in the vicinity will think so. It just looks terrible. In this case, we recommend you record the deflection and then consult your pallet rack dealer and/or the manufacturer if the deflection appears to be unreasonably beyond the published limits.

Should You Replace or Repair?

It is recommended that all damaged rack be isolated and evaluated by a qualified professional prior to repair or replacement of the damaged components. If the system required a permit from your local municipality when originally installed, it’s best to ensure an engineer is part of any repair process. This does not mean that the engineer has to perform the assessment, however the engineer should approve the proposed repairs and should ensure that the appropriate information is sufficiently documented.

In some situations it may be more economical to remove the damaged section of the upright and to replace it with a pre-engineered rack repair kit. Such kits are typically bolted or welded in place and anchored to the floor. In other situations, it may make more sense to replace the entire beam or upright.

Where replacement or repair kits are not an option, you can perform a welded field repair on a rack system. Any field repairs must be made in accordance with applicable American Welding Society (AWS) codes

A. Beams

When it comes to repairing or replacing a beam, it is best to just replace the beam. The structural integrity will be greatly reduced if cut or field welded and no repair kits exist (that we know of). If they did, they’d probably look just like a new beam.

B. Upright Columns

Uprights are going to depend on the importance of aesthetics vs. cost. It is typically more economical to repair a column than it is to replace it.

| Repair | Replace |

|---|---|

| Bolted or welded repair kit | Utilize original equipment |

| Noticeable fix | Like-new look |

| $165 to $285/ea, installed | $235 to $350/ea, installed |

When repairing rack systems, it’s important to evaluate the loads that are imparted on the damaged component, not just on the specific member being repaired. This is especially important with older systems that may have been moved or reconfigured as this can dramatically reduce the load capacity of a system. RMI provides the following example:

An owner reconfigured a rack without considering how it might affect the load capacity of the system. The owner’s maintenance department removed the lower level of a push-back rack system to allow for additional clearance for fork lifts to drive under the rack to place floor-level pallets. The owner did not realize that this reconfiguration reduced the capacity of the rack system from 3,000 lbs per pallet to 1,800 lbs per pallet because the unsupported span of the uprights was increased. The owner continued to store 3,000 lbs pallets on the system, thereby exposing lift truck operators to driving under a system that was loaded 66% over its rated capacity.

A Checklist for Regular Rack Inspections

Now that the rack is repaired or replaced and the facility is in great shape. How are you going to ensure it stays that way? Regular future inspections are a great way to ensure damage is caught often and early. Such inspections are typically the responsibility of either the maintenance staff, the safety committee or a professional third-party.

The page of the guide includes a check-list to assist in future rack inspections.

- What is the size and weight of the load today? Has it changed in any way?

- What is the size and weight of the average load? Has this change in any way?

- What is the footprint of the loads? Have they changed?

- Are the loads at the same level of quality? (Damaged pallets may cause unusual point loads on beams)

- Has any of the equipment changed?

- Has it been maintained so that it has the same operating characteristics as it did originally?

- Has other equipment been added which looks the same but is slightly different?

- Are the original clearances still appropriate?

- Has anything been added to the building which might reduce clearances?

- Has the overall layout or warehouse design changed?

- Is the overall rack plumb in both directions?

- Do the faces of all the loads form a moth, clean, “wall” in the aisle?

- Are there any “special” areas to be noted?

- Are there any special conditions such as a corrosive atmosphere which might produce adverse effects?

- What is the general “housekeeping” condition?

- Are all of the anchors in place and tight?

- Does the slab exhibit any signs of unusual cracking or decay?

- Are all of the beam “safety” locks in place?

- Do any of the beams exhibit an upward bow or have contact marks on the bottom?

- Do any of the beams appear to have excessive deflection?

- Are all of the accessories, whatever they may be, in place and in good condition?

- Do any of the posts exhibit excessive damage?

- Are there any hole patterns where the material is torn or otherwise damaged?

- Do all of the welds appear to be undamaged?

- Is the upright bracing all straight and undamaged?

- Do any of the posts show signs of rust or other deterioration especially at the bottom?

- Do any of the posts need to have their protective devices repaired or replaced?

You may wish to include other items such as the fire protection system to make maximum use of your time in the facility.

Now you’re armed to assess the status of your rack system…

From initial planning through start-up and equipment service — we are with you every step of the way — to help you meet the many challenges of warehousing, industry and commercial distribution.

With SRS’s in-house design, project management and installation teams, you can focus on fulfilling customer orders and forget about managing the execution.

This guide was developed by BMH Equipment, LLC (“BMH”) and represents suggested practices and considerations for repairing or replacing damaged racks. It is intended to provide useful information and guidance. It is advisory only and should only be regarded as a simple tool that can be used at the election of the individual. The previous information does not constitute a comprehensive safety program, cannot guard against pitfalls in operating, selecting and purchasing a pallet racking system, its repair or its replacement and should not be relied upon as such.

Disclaimer of Liability. BMH assumes no responsibility and disclaims all liability of any kind, however arising, as a result of acceptance or use or alleged use of this guide. Anyone using this guide specifically understands and agrees that BMH, its members, officers and employees shall not be liable under any legal theory of any kind for any action or failure to act with respect to the repair, replacement, design, erection, installation, manufacture and preparation for sale of anything covered by this guide or any other activity covered by this guide. Any use of this information must independently be determined and verified by the user to be in accordance with applicable federal, state and local laws and regulations.

Disclaimer of Warranty. BMH makes NO WARRANTIES of any kind, express or implied, in connection with the information in this guide and SPECIFICIALLY DISCLAIM ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNEES FOR PARTICULAR PURPOSE.

Indemnification. By referring to or otherwise employing this guide, its user agrees to defend, protect, indemnify, and hold BMH, its members, officers, agents and employees harmless from and against all claims, losses, expenses, damages and liabilities, direct, incidental, or consequential, arising from acceptance or use or alleged use of this document. The intent of this provision is to absolve and protect BMH, its members, officers, agents and employees from any and all loss relating in any way to this document, including those resulting from the user’s own negligence.

Sources

Design it Right – Perspectives on Material Handling

RMI, “Guideline for the Assessment and Repair or Replacement of Damaged Rack – Version 1.00”, 2014